Inspection and corrosion management services

MainTech, a subsidiary of Altrad Services, is an inspection and corrosion engineering company. We believe in combining knowledge of inspection and corrosion to build one system to manage both inspection activities and the activities related to the material and corrosion discipline; which is often called the Total Corrosion & Inspection Management System. This means that MainTech is involved in all aspects of an asset’s lifecycle, including everything from topside, to subsea and onshore.

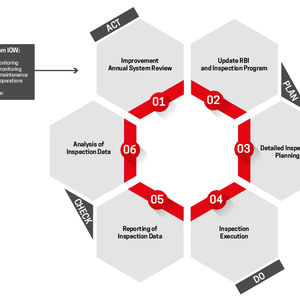

- Development of inspection philosophies and strategies (plan)

- Facilitate and participate in risk-based-inspection (RBI) analysis (plan), providing Risk analyses for a wide range of asset classes:

- Static process equipment and piping

- Pipelines/flowlines/risers

- Structures (both subsea and topside/onshore)

- Detailed planning including work packing (plan)

- Manage inspection campaigns offshore/onshore (do)

- Execute inspections, often with Altrad Services teams (do), typical examples being:

- Visual inspections including using robotic equipment and video probes

- Paint inspections

- Corrosion under insulation (CUI) inspections

- Structural inspections

- Vibration surveys

- NDT inspections

- Evaluate and report inspection results (check)

- System reviews – combining inspection results with experience from the assets and our corrosion knowledge (corrosion management systems), to obtain revised and improved inspection programs (act)

MainTech also has the knowledge and experience to participate in and manage a total review of our clients’ inspection systems, including the provision of recommendations and improvements for an efficient organisation.

A corrosion management system includes: building a system that defines all possible threats and barriers for each item in the asset. Barriers shall then be monitored, either by process data, monitoring equipment, sampling or inspection. All parameters defined to be monitored shall be included into the Integrity Operating Window (IOW) and followed up continuously.

Typical services provided by MainTech (Altrad Services) are:

- Development of philosophies and strategies for how to control corrosion and material degradation

- Definition of all threats for an asset

- Definition of barriers for all threats and how to monitor the barriers (IOW)

- Follow-up of IOW

- Contribution to and management of root cause analysis when material degradation is discovered

- General consulting regarding corrosion and material issues